Abstract

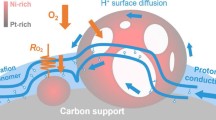

This study aimed to determine nanoscopic interactions between constituent distributions and effective transport processes in pre- and post-compressed catalyst layers (CLs) of proton exchange membrane fuel cells (PEMFCs) to improve cell performance and reduce cell cost. To this end, quaternion CLs were reconstructed with carbon black-supported platinum, proton-conductive ionomer, and gas-transporting pores. The percolation cluster labeling method was implemented to estimate the interconnectivity of Pt/C, ionomer, and the gas-transporting void phase in pre- and post-compressed CLs with a 98% confidence level. The effect of compression on the interconnectivity of Pt/C, ionomer, and pores was examined for a range of ionomer-to-carbon (I/C) weight ratios. Next, lattice Boltzmann direct numerical simulations (LB-DNSs) with fine-lattice grids were introduced to estimate the reactant gas transport characteristics for the pre- and post-compressed CLs. The results indicate that the dead pore fraction and the tortuosity of the void phase are directly proportional to compression, whereas the permeability of the CL is inversely proportional to compression. Subsequently, the morphology-based and the transport-based effective catalyst utilization factors (M- and T-ECUFs) were compared as a function of the I/C ratio under various compression conditions. Detailed simulations further revealed that the M-ECUF, representing the ideal catalyst utilization case for an electrochemical reaction, usually appears to be greater than the T-ECUF and compression has a positive effect on ECUF, particularly for low I/C ratios, because of reduced local resistance on the surface of the catalyst by compression.

Similar content being viewed by others

Data availability

All data underlying the results are available as part of the article and no additional source data are required.

Abbreviations

- c :

-

Lattice speed

- d :

-

Pore diameter, m

- D :

-

Diffusion coefficient, m2/s

- e :

-

Directional matrix

- f :

-

Density distribution function

- I/C :

-

Ionomer-to-carbon ratio

- IR :

-

Interconnectivity ratio

- k :

-

Boltzmann constant, J/K

- K :

-

Intrinsic permeability, m2

- l :

-

Through-plane direction thickness

- L :

-

Characteristic length, m

- m :

-

Mass in a unit volume of the catalyst layer, g/cm3

- M :

-

Molar mass, kg/mol

- P :

-

Static pressure, N/m2

- PF :

-

Platinum fraction parameters

- R :

-

Universal gas constant, J/mol K

- t :

-

Lattice time

- T :

-

Thermodynamic temperature, K

- u :

-

Velocity, m/s

- x :

-

Abscissa in the in-plane direction

- X :

-

Mass fraction

- y :

-

Ordinate in the in-plane direction

- z :

-

Through-plane direction

- \(\gamma\) :

-

Loading of the component, mg/cm2

- \(\rho\) :

-

Density, g/cm3

- \(\phi\) :

-

Volume fraction

- \(\tau\) :

-

Relaxation time

- \(\omega\) :

-

Weight factor

- \(\nu\) :

-

Kinematic viscosity, m2/s

- \(\lambda\) :

-

Mean free path, m

- \(\sigma\) :

-

Effective cross-sectional area for collision, m2

- \(\mu\) :

-

Dynamic viscosity, kg/m s

- \(\Gamma\) :

-

Effective catalyst utilization factor

- c :

-

Carbon

- eff :

-

Effective value

- eq :

-

Equilibrium

- in :

-

Ionomer

- pore :

-

Pore

- porosity :

-

Bulk porosity

- pt :

-

Platinum

- avg :

-

Average value

- B :

-

Boltzmann constant value

- c :

-

Carbon

- CL :

-

Catalyst layer

- e :

-

Streamline in a pore structure

- EA :

-

Electron-accessed value

- Gas :

-

Gas phase value

- GE :

-

Gas-exposed value

- i :

-

D3Q19 lattice direction

- in :

-

Ionomer

- Kn :

-

Knudsen value

- lattice :

-

Lattice Boltzmann method value

- M :

-

Morphology-based effective value

- Mfp :

-

Mean free path

- N 2 :

-

Nitrogen value

- O 2 :

-

Oxygen value

- PA :

-

Proton-accessed

- Pt :

-

Platinum

- Pt/C :

-

Platinum/carbon

- r :

-

Lattice Boltzmann method relaxation value

- s :

-

Speed of sound

- total :

-

Total value of nanoparticles

- T :

-

Transport-based effective value

- x :

-

Abscissa in the in-plane direction

- y :

-

Ordinate in the in-plane direction

- z :

-

Through-plane direction

- w :

-

Wall value

References

Chen, L., He, A., Zhao, J., Kang, Q., Li, Z. Y., Carmeliet, J., Shikazono, N., & Tao, W. Q. (2022). Pore-scale modeling of complex transport phenomena in porous media. Progress in Energy and Combustion Science, 88, 100968. https://doi.org/10.1016/J.PECS.2021.100968

Fu, Y. L., Zhang, B., Zhu, X., Ye, D. D., Sui, P. C., & Djilali, N. (2020). Pore-scale modeling of oxygen transport in the catalyst layer of air-breathing cathode in membraneless microfluidic fuel cells. Applied Energy, 277, 115536. https://doi.org/10.1016/J.APENERGY.2020.115536

Deng, X., Zhang, J., Fan, Z., Tan, W., Yang, G., Wang, W., Zhou, W., & Shao, Z. (2020). Understanding and engineering of multiphase transport processes in membrane electrode assembly of proton-exchange membrane fuel cells with a focus on the cathode catalyst layer: A review. Energy & Fuels., 34, 9175–9188. https://doi.org/10.1021/ACS.ENERGYFUELS.0C02101

Deng, H., Hou, Y., Chen, W., Pan, F., & Jiao, K. (2019). Lattice Boltzmann simulation of oxygen diffusion and electrochemical reaction inside catalyst layer of PEM fuel cells. International Journal of Heat and Mass Transfer, 143, 118538. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118538

Satjaritanun, P., Hirano, S., Zenyuk, I. V., Weidner, J. W., Tippayawong, N., & Shimpalee, S. (2020). Numerical study of electrochemical kinetics and mass transport inside nano-structural catalyst layer of PEMFC using lattice Boltzmann agglomeration method. Journal of the Electrochemical Society, 167, 013516. https://doi.org/10.1149/2.0162001JES/XML

Inoue, G., Yokoyama, K., Ooyama, J., Terao, T., Tokunaga, T., Kubo, N., & Kawase, M. (2016). Theoretical examination of effective oxygen diffusion coefficient and electrical conductivity of polymer electrolyte fuel cell porous components. Journal of Power Sources, 327, 610–621. https://doi.org/10.1016/j.jpowsour.2016.07.107

Zhang, R., He, P., Bai, F., Chen, L., & Tao, W. Q. (2021). Multiscale modeling of proton exchange membrane fuel cells by coupling pore-scale models of the catalyst layers and cell-scale models. International Journal of Green Energy, 18, 1147–1160. https://doi.org/10.1080/15435075.2021.1891912

Wu, C. W., Zhang, W., Han, X., Zhang, Y. X., & Ma, G. J. (2020). A systematic review for structure optimization and clamping load design of large proton exchange membrane fuel cell stack. Journal of Power Sources, 476, 228724. https://doi.org/10.1016/J.JPOWSOUR.2020.228724

Hwang, Y. S., Choi, H., Cho, G. Y., et al. (2014). Effect of compression thickness on performance of gas diffusion layer of direct methanol fuel cells. International Journal of Precision Engineering and Manufacturing-Green Technology 1, 215–221. https://doi.org/10.1007/s40684-014-0027-y

Shin, S., Liu, J., Chung, S. J., & Um, S. (2020). Numerical development of concentric cylinder-shaped dual-functional catalyst structure for enhanced charge transport in polymer electrolyte fuel cells. Advanced Theory and Simulations, 3, 2000096. https://doi.org/10.1002/adts.202000096

Shin, S., Liu, J., Akbar, A., & Um, S. (2019). Nanoscale transport characteristics and catalyst utilization of vertically aligned carbon nanotube catalyst layers for fuel cell applications: Comprehensive stochastic modeling of composite morphological structures. Journal of Catalysis, 377, 465–479. https://doi.org/10.1016/J.JCAT.2019.07.053

Shin, S., Kim, A. R., & Um, S. (2016). Integrated statistical and nano-morphological study of effective catalyst utilization in vertically aligned carbon nanotube catalyst layers for advanced fuel cell applications. Electrochimica Acta, 207, 187–197. https://doi.org/10.1016/j.electacta.2016.04.178

Shin, S., Kim, A. R., & Um, S. (2018). Computational prediction of nanoscale transport characteristics and catalyst utilization in fuel cell catalyst layers by the lattice Boltzmann method. Electrochimica Acta, 275, 87–99. https://doi.org/10.1016/j.electacta.2018.04.138

Shin, S., Kim, A. R., & Um, S. (2016). Statistical prediction of fuel cell catalyst effectiveness: Quasi-random nano-structural analysis of carbon sphere-supported platinum catalysts. International Journal of Hydrogen Energy, 41, 9507–9520. https://doi.org/10.1016/j.ijhydene.2016.04.013

Kang, H., Kwon, S. H., Lawler, R., Lee, J. H., Doo, G., Kim, H. T., Yim, S. D., Jang, S. S., & Lee, S. G. (2020). Nanostructures of Nafion film at platinum/carbon surface in catalyst layer of PEMFC: Molecular dynamics simulation approach. Journal of Physical Chemistry C, 124, 21386–21395. https://doi.org/10.1021/ACS.JPCC.0C03651/SUPPL_FILE/JP0C03651_SI_001.PDF

Inoue, G., Ohnishi, T., So, M., Park, K., Ono, M., & Tsuge, Y. (2019). Simulation of carbon black aggregate and evaluation of ionomer structure on carbon in catalyst layer of polymer electrolyte fuel cell. Journal of Power Sources, 439, 227060. https://doi.org/10.1016/j.jpowsour.2019.227060

Wang, G., Mukherjee, P. P., & Wang, C. Y. (2006). Direct numerical simulation (DNS) modeling of PEFC electrodes: Part I. Regular microstructure. Electrochimica Acta, 51, 3139–3150. https://doi.org/10.1016/J.ELECTACTA.2005.09.002

Wang, G., Mukherjee, P. P., & Wang, C. Y. (2006). Direct numerical simulation (DNS) modeling of PEFC electrodes: Part II. Random microstructure. Electrochimica Acta, 51, 3151–3160. https://doi.org/10.1016/J.ELECTACTA.2005.09.003

Mukherjee, P. P., & Wang, C.-Y. (2006). Stochastic microstructure reconstruction and direct numerical simulation of the PEFC catalyst layer. Journal of the Electrochemical Society, 153, A840. https://doi.org/10.1149/1.2179303/XML

Wang, G., Mukherjee, P. P., & Wang, C. Y. (2007). Optimization of polymer electrolyte fuel cell cathode catalyst layers via direct numerical simulation modeling. Electrochimica Acta, 52, 6367–6377. https://doi.org/10.1016/J.ELECTACTA.2007.04.073

Kok, M. D. R., Jervis, R., Tranter, T. G., Sadeghi, M. A., Brett, D. J. L., Shearing, P. R., & Gostick, J. T. (2019). Mass transfer in fibrous media with varying anisotropy for flow battery electrodes: Direct numerical simulations with 3D X-ray computed tomography. Chemical Engineering Science, 196, 104–115. https://doi.org/10.1016/j.ces.2018.10.049

Suter, T. A. M., Smith, K., Hack, J., Rasha, L., Rana, Z., Angel, G. M. A., Shearing, P. R., Miller, T. S., & Brett, D. J. L. (2021). Engineering catalyst layers for next-generation polymer electrolyte fuel cells: A review of design, materials, and methods. Advanced Energy Materials, 11, 2101025. https://doi.org/10.1002/AENM.202101025

Sun, X., Yu, H., Zhou, L., Gao, X., Zeng, Y., Yao, D., He, L., & Shao, Z. (2020). Influence of platinum dispersity on oxygen transport resistance and performance in PEMFC. Electrochimica Acta, 332, 135474. https://doi.org/10.1016/J.ELECTACTA.2019.135474

Chen, L., Zhang, R., Kang, Q., & Tao, W. Q. (2020). Pore-scale study of pore-ionomer interfacial reactive transport processes in proton exchange membrane fuel cell catalyst layer. Chemical Engineering Journal, 391, 123590. https://doi.org/10.1016/j.cej.2019.123590

Chen, L., Zhang, R., Min, T., Kang, Q., & Tao, W. (2018). Pore-scale study of effects of macroscopic pores and their distributions on reactive transport in hierarchical porous media. Chemical Engineering Journal, 349, 428–437. https://doi.org/10.1016/J.CEJ.2018.05.106

Liu, J., Chung, S. J., Akbar, A., et al. (2022). Morphological effects of polytetrafluoroethylene meniscus formation on microscopic transport properties of inhomogeneous random porous gas diffusion media for electrochemical applications. International Journal of Precision Engineering and Manufacturing-Green Technology 9, 1101–1119. https://doi.org/10.1007/s40684-021-00361-4

Chen, L., Zhang, R., He, P., Kang, Q., He, Y. L., & Tao, W. Q. (2018). Nanoscale simulation of local gas transport in catalyst layers of proton exchange membrane fuel cells. Journal of Power Sources, 400, 114–125. https://doi.org/10.1016/j.jpowsour.2018.07.099

Akbar, A., & Um, S. (2022). Influence of external clamping pressure on nanoscopic mechanical deformation and catalyst utilization of quaternion PtC catalyst layers for PEMFCs. Renewable Energy, 194, 195–210. https://doi.org/10.1016/J.RENENE.2022.05.112

Zheng, B., Wang, Z., & Wang, Y. (2022). Porous media flow field for polymer electrolyte membrane fuel cell: Depression of gas diffusion layer intrusion, deformation, and delamination. International Journal of Energy Research. https://doi.org/10.1002/ER.7630

Wang, Y. J., Fang, B., Li, H., Bi, X. T., & Wang, H. (2016). Progress in modified carbon support materials for Pt and Pt-alloy cathode catalysts in polymer electrolyte membrane fuel cells. Progress in Materials Science, 82, 445–498. https://doi.org/10.1016/J.PMATSCI.2016.06.002

Li, W. Z., Yang, W. W., Zhang, W. Y., Qu, Z. G., & He, Y. L. (2019). Three-dimensional modeling of a PEMFC with serpentine flow field incorporating the impacts of electrode inhomogeneous compression deformation. International Journal of Hydrogen Energy, 44, 22194–22209. https://doi.org/10.1016/J.IJHYDENE.2019.06.187

Atyabi, S. A., Afshari, E., Wongwises, S., Yan, W. M., Hadjadj, A., & Shadloo, M. S. (2019). Effects of assembly pressure on PEM fuel cell performance by taking into accounts electrical and thermal contact resistances. Energy, 179, 490–501. https://doi.org/10.1016/j.energy.2019.05.031

Li, S., & Sundén, B. (2018). Effects of gas diffusion layer deformation on the transport phenomena and performance of PEM fuel cells with interdigitated flow fields. International Journal of Hydrogen Energy, 43, 16279–16292. https://doi.org/10.1016/J.IJHYDENE.2018.07.064

Tanaka, S., Bradfield, W. W., Legrand, C., & Malan, A. G. (2016). Numerical and experimental study of the effects of the electrical resistance and diffusivity under clamping pressure on the performance of a metallic gas-diffusion layer in polymer electrolyte fuel cells. Journal of Power Sources, 330, 273–284. https://doi.org/10.1016/J.JPOWSOUR.2016.08.121

Froning, D., Brinkmann, J., Reimer, U., Schmidt, V., Lehnert, W., & Stolten, D. (2013). 3D analysis, modeling and simulation of transport processes in compressed fibrous microstructures, using the lattice Boltzmann method. Electrochimica Acta, 110, 325–334. https://doi.org/10.1016/j.electacta.2013.04.071

Mason, T. J., Millichamp, J., Neville, T. P., El-Kharouf, A., Pollet, B. G., & Brett, D. J. L. (2012). Effect of clamping pressure on ohmic resistance and compression of gas diffusion layers for polymer electrolyte fuel cells. Journal of Power Sources, 219, 52–59. https://doi.org/10.1016/j.jpowsour.2012.07.021

Malekian, A., Salari, S., Tam, M., Oldknow, K., Djilali, N., & Bahrami, M. (2019). Compressive behaviour of thin catalyst layers. Part I—Experimental study. International Journal of Hydrogen Energy, 44, 18450–18460. https://doi.org/10.1016/J.IJHYDENE.2019.04.134

Malekian, A., Salari, S., Tam, M., Djilali, N., & Bahrami, M. (2019). Compressive behaviour of thin catalyst layers. Part II—Model development and validation. International Journal of Hydrogen Energy, 44, 18461–18471. https://doi.org/10.1016/j.ijhydene.2019.04.135

Malekian, A., Salari, S., Stumper, J., Djilali, N., & Bahrami, M. (2019). Effect of compression on pore size distribution and porosity of PEM fuel cell catalyst layers. International Journal of Hydrogen Energy, 44, 23396–23405. https://doi.org/10.1016/j.ijhydene.2019.07.036

Zhang, H., Rahman, M. A., Mojica, F., Sui, P. C., & Chuang, P. A. (2021). A comprehensive two-phase proton exchange membrane fuel cell model coupled with anisotropic properties and mechanical deformation of the gas diffusion layer. Electrochimica Acta, 382, 138273. https://doi.org/10.1016/J.ELECTACTA.2021.138273

Qiao, Z., Wang, C., Zeng, Y., Spendelow, J. S., & Wu, G. (2021). Advanced nanocarbons for enhanced performance and durability of platinum catalysts in proton exchange membrane fuel cells. Small (Weinheim an der Bergstrasse, Germany). https://doi.org/10.1002/smll.202006805

Kobayashi, A., Fujii, T., Harada, C., Yasumoto, E., Takeda, K., Kakinuma, K., & Uchida, M. (2021). Effect of Pt and ionomer distribution on polymer electrolyte fuel cell performance and durability. ACS Applied Energy Materials 4, 2307–2317. https://doi.org/10.1021/ACSAEM.0C02841

Yakovlev, Y. V., Lobko, Y. V., Vorokhta, M., Nováková, J., Mazur, M., Matolínová, I., & Matolín, V. (2021). Ionomer content effect on charge and gas transport in the cathode catalyst layer of proton-exchange membrane fuel cells. Journal of Power Sources, 490, 229531. https://doi.org/10.1016/J.JPOWSOUR.2021.229531

Ott, S., Orfanidi, A., Schmies, H., Anke, B., Nong, H. N., Hübner, J., Gernert, U., Gliech, M., Lerch, M., & Strasser, P. (2019). Ionomer distribution control in porous carbon-supported catalyst layers for high-power and low Pt-loaded proton exchange membrane fuel cells. Nature Materials, 19(1), 77–85. https://doi.org/10.1038/s41563-019-0487-0

Van Dao, D., Adilbish, G., Lee, I. H., & Yu, Y. T. (2019). Enhanced electrocatalytic property of Pt/C electrode with double catalyst layers for PEMFC. International Journal of Hydrogen Energy, 44, 24580–24590. https://doi.org/10.1016/J.IJHYDENE.2019.07.156

Inaba, M., Jensen, A. W., Sievers, G. W., Escudero-Escribano, M., Zana, A., & Arenz, M. (2018). Benchmarking high surface area electrocatalysts in a gas diffusion electrode: Measurement of oxygen reduction activities under realistic conditions. Energy & Environmental Science, 11, 988–994. https://doi.org/10.1039/C8EE00019K

Akbar, A., Liu, J., Chung, S.-J., & Um, S. (2021). Statistical characterization of non-linear microscopic mechanical deformation through randomly oriented fibrous porous transport layers for advanced electrochemical energy systems. Renewable Energy, 178, 1106–1118. https://doi.org/10.1016/J.RENENE.2021.07.005

Arora, K. R. (1989). Soil mechanics and foundation engineering. Standard Publishers.

Cetinbas, F. C., Ahluwalia, R. K., Kariuki, N., De Andrade, V., Fongalland, D., Smith, L., Sharman, J., Ferreira, P., Rasouli, S., & Myers, D. J. (2017). Hybrid approach combining multiple characterization techniques and simulations for microstructural analysis of proton exchange membrane fuel cell electrodes. Journal of Power Sources, 344, 62–73. https://doi.org/10.1016/j.jpowsour.2017.01.104

Yin, Y., Wu, S., Qin, Y., Liu, Y., & Zhang, J. (2021). Evaluating the effective diffusion coefficient of reactant gas in the catalyst layer of PEMFC using the fractal method considering the pore size distribution. Nano Select, 2, 116–120. https://doi.org/10.1002/NANO.202000136

Guan, S., Zhou, F., Tan, J., & Pan, M. (2020). Influence of pore size optimization in catalyst layer on the mechanism of oxygen transport resistance in PEMFCs. Progress in Natural Science: Materials International, 30, 839–845. https://doi.org/10.1016/J.PNSC.2020.08.017

Fuller, E. N., Schettler, P. D., & Giddings, J. C. (1966). New method for prediction of binary gas-phase diffusion coefficients. Industrial & Engineering Chemistry Research, 58, 18–27. https://doi.org/10.1021/ie50677a007

Liu, J., Shin, S., & Um, S. (2019). Comprehensive statistical analysis of heterogeneous transport characteristics in multifunctional porous gas diffusion layers using lattice Boltzmann method for fuel cell applications. Renewable Energy, 139, 279–291. https://doi.org/10.1016/j.renene.2019.02.089

Sharma, R., & Andersen, S. M. (2018). Quantification on degradation mechanisms of polymer electrolyte membrane fuel cell catalyst layers during an accelerated stress test. ACS Catalysis, 8, 3424–3434. https://doi.org/10.1021/ACSCATAL.8B00002/SUPPL_FILE/CS8B00002_SI_001.PDF

Gwak, G., Lee, J., Ghasemi, M., Choi, J., Lee, S. W., Jang, S. S., & Ju, H. (2020). Analyzing oxygen transport resistance and Pt particle growth effect in the cathode catalyst layer of polymer electrolyte fuel cells. International Journal of Hydrogen Energy, 45, 13414–13427. https://doi.org/10.1016/J.IJHYDENE.2020.03.080

Tjaden, B., Cooper, S. J., Brett, D. J. L., Kramer, D., & Shearing, P. R. (2016). On the origin and application of the Bruggeman correlation for analysing transport phenomena in electrochemical systems. Current Opinion in Chemical Engineering., 12, 44–51. https://doi.org/10.1016/j.coche.2016.02.006

Yu, Z., & Carter, R. N. (2010). Measurement of effective oxygen diffusivity in electrodes for proton exchange membrane fuel cells. Journal of Power Sources, 195, 1079–1084. https://doi.org/10.1016/J.JPOWSOUR.2009.08.065

Braaten, J. P., Kariuki, N. N., Myers, D. J., Blackburn, S., Brown, G., Park, A., & Litster, S. (2022). Integration of a high oxygen permeability ionomer into polymer electrolyte membrane fuel cell cathodes for high efficiency and power density. Journal of Power Sources, 522, 230821. https://doi.org/10.1016/J.JPOWSOUR.2021.230821

Keller, N., & von Unwerth, T. (2022). Advanced parametric model for analysis of the influence of channel cross section dimensions and clamping pressure on current density distribution in PEMFC. Applied Energy, 307, 118132. https://doi.org/10.1016/J.APENdERGY.2021.118132

Acknowledgements

This work was supported by the Korea Institute for Advancement of Technology [Grant Number 1415183958 (P0018649)]; Korea Institute of Energy Technology Evaluation and Planning [Grant Number 1415181294 (20223030030110)]; and the Korea Evaluation Institute of Industrial Technology [Grant Number 1415186266 (20012133)].

Author information

Authors and Affiliations

Contributions

SP conceptualization, methodology, validation, investigation, writing. AA data curation, resources, software, visualization, writing. JL visualization, software. Y-BK visualization. SU conceptualization, investigation, supervision, project administration, funding acquisition, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The author declares that there are no competing interests to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Park, S., Akbar, A., Lee, J. et al. Nanoscopic Post-Compression Effects on Transport Phenomena and Electrochemical Utilization in Quaternion Catalyst Layers for Fuel Cell Applications. Int. J. of Precis. Eng. and Manuf.-Green Tech. 11, 463–479 (2024). https://doi.org/10.1007/s40684-023-00564-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-023-00564-x