Abstract

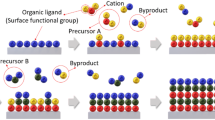

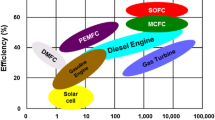

Atomic layer deposition (ALD) has recently attracted attention as a technique to synthesize and engineer high-performance catalysts and electrodes for fuel cells. Unique advantages of the ALD process include surface conformality and film uniformity along nano-scale features and the ability to deposit one atom layer or less per deposition cycle, enabling atomic-scale modification of the composition and morphology of the material surface. Many recent reports have demonstrated the effectiveness of the ALD surface modification strategy for the development of novel fuel cell materials. For enhancement of fuel cell performance, development of superior electrocatalytic electrodes is essential as a significant portion of energy loss occurs due to the charge transfer reaction either on the surface of electrodes or at the interfaces between electrodes and electrolytes. Therefore, ALD is considered a key fabrication process to design and engineer high-performance fuel cell systems. This review covers the important recent developments advanced electrode materials for solid oxide fuel cells (SOFCs) provided by the unique abilities of ALD for surface engineering and interface modification. Performance enhancement and related mechanisms are also discussed in depth.

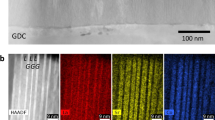

Reproduced from Ref. [57] with permission from The Electrochemical Society

Reproduced from Ref. [135] with permission from American Chemical Society

Reproduced from Ref. [149] with permission from American Chemical Society

Similar content being viewed by others

References

Zhang, J., Zheng, C., Cha, S. W., & Duan, S. (2016). Co-state variable determination in pontryagin’s minimum principle for energy management of hybrid vehicles. International Journal of Precision Engineering and Manufacturing, 17(9), 1215–1222.

Zheng, C., & Cha, S. W. (2017). Real-time application of pontryagin’s minimum principle to fuel cell hybrid buses based on driving characteristics of buses. International Journal of Precision Engineering and Manufacturing-Green Technology, 4(2), 199–200.

Yi, H. S., Jeong, J. B., Cha, S. W., & Zheng, C. H. (2018). Optimal component sizing of fuel cell-battery excavator based on workload. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(1), 103–110.

Yue, D., Pandya, S., & You, F. (2016). Integrating hybrid life cycle assessment with multiobjective optimization: a modeling framework. Environmental Science and Technology, 50(3), 1501–1509.

Ütu, F. G., & Holmes, S. M. (2011). Characterization and fuel cell performance analysis of polyvinylalcohol-mordenite mixed-matrix membranes for direct methanol fuel cell use. Electrochimica Acta, 56(24), 8446–8456.

McIntosh, S., & Gorte, R. J. (2004). Direct hydrocarbon solid oxide fuel cells. Chemical Reviews, 104(10), 4845–4865.

Mogensen, M., & Kammer, K. (2003). Conversion of hydrocarbons in solid oxide fuel cells. Annual Review of Materials Science, 33, 321–331.

Park, S., Vohs, J. M., & Gorte, R. J. (2000). Direct oxidation of hydrocarbons in a solid-oxide fuel cell. Nature, 404(6775), 265–267.

Murray, E. P., Harris, S. J., Liu, J., & Barnett, S. A. (2006). Direct solid oxide fuel cell operation using isooctane. Electrochemical and Solid-State Letters, 9(6), A292–A294.

Primdahl, S., & Mogensen, M. (1997). Oxidation of hydrogen on ni/yttria-stabilized zirconia cermet anodes. Journal of the Electrochemical Society, 144(10), 3409–3419.

Jiang, Y., & Virkar, A. V. (2001). A high performance, anode-supported solid oxide fuel cell operating on direct alcohol. Journal of the Electrochemical Society, 148(7), A706–A709.

Homel, M., Gür, T. M., Koh, J. H., & Virkar, A. V. (2010). Carbon monoxide-fueled solid oxide fuel cell. Journal of Power Sources, 195(19), 6367–6372.

Gür, T. M., Homel, M., & Virkar, A. V. (2010). High performance solid oxide fuel cell operating on dry gasified coal. Journal of Power Sources, 195(4), 1085–1090.

Gür, T. M. (2013). Critical review of carbon conversion in carbon fuel cells. Chemical Reviews, 113(8), 6179–6206.

Evans, A., Bieberle-Hütter, A., Rupp, J. L. M., & Gauckler, L. J. (2009). Review on microfabricated micro-solid oxide fuel cell membranes. Journal of Power Sources, 194(1), 119–129.

Cassir, M., Ringuedé, A., & Niinistö, L. (2010). Input of atomic layer deposition for solid oxide fuel cell applications. Journal of Materials Chemistry, 20(41), 8987–8993.

Elam, J. W., Dasgupta, N. P., & Prinz, F. B. (2011). ALD for clean energy conversion, utilization, and storage. MRS Bulletin, 36(11), 899–906.

Peng, Q., Lewis, J. S., Hoertz, P. G., Glass, J. T., & Parsons, G. N. (2012). Atomic layer deposition for electrochemical energy generation and storage systems. Journal of Vacuum Science and Technology A, 30(1), 010803.

Shim, J. H., Kang, S., Cha, S. W., Lee, W., Kim, Y. B., Park, J. S., et al. (2013). Atomic layer deposition of thin-film ceramic electrolytes for high-performance fuel cells. Journal of Materials Chemistry A, 1(41), 12695–12705.

Johnson, R. W., Hultqvist, A., & Bent, S. F. (2014). A brief review of atomic layer deposition: from fundamentals to applications. Materials Today, 17(5), 236–246.

An, J., Shim, J. H., Kim, Y. B., Park, J. S., Lee, W., Gür, T. M., et al. (2014). MEMS-based thin-film solid-oxide fuel cells. MRS Bulletin, 39(9), 798–804.

Oneill, B. J., Jackson, D. H. K., Lee, J., Canlas, C., Stair, P. C., Marshall, C. L., et al. (2015). Catalyst design with atomic layer deposition. ACS Catalysis, 5(3), 1804–1825.

Tanveer, W. H., Ji, S., Yu, W., & Cha, S. W. (2015). Characterization of atomic layer deposited and sputtered yttria-stabilized-zirconia thin films for low-temperature solid oxide fuel cells. International Journal of Precision Engineering and Manufacturing, 16(10), 2229–2234.

Lu, J., Elam, J. W., & Stair, P. C. (2016). Atomic layer deposition—sequential self-limiting surface reactions for advanced catalyst “bottom-up” synthesis. Surf Sci Rep, 71(2), 410–472.

Cheng, N., Shao, Y., Liu, J., & Sun, X. (2016). Electrocatalysts by atomic layer deposition for fuel cell applications. Nano Energy, 29, 220–242.

Ji, S., Ha, J., Park, T., Kim, Y., Koo, B., Kim, Y. B., et al. (2016). Substrate-dependent growth of nanothin film solid oxide fuel cells toward cost-effective nanostructuring. International Journal of Precision Engineering and Manufacturing-Green Technology, 3(1), 35–39.

Lee, Y. H., Chang, I., Cho, G. Y., Park, J., Yu, W., Tanveer, W. H., et al. (2018). Thin film solid oxide fuel cells operating below 600°C: a review. International Journal of Precision Engineering and Manufacturing-Green Technology, 5(3), 441–453.

Suntola, T. (1992). Atomic layer epitaxy. Thin Solid Films, 216(1), 84–89.

George, S. M., Ott, A. W., & Klaus, J. W. (1996). Surface chemistry for atomic layer growth. Journal of Physical Chemistry, 100(31), 13121–13131.

Hurle, D. T. (1993). Handbook of crystal growth. Amsterdam: North Holland.

Goodman, C. H. L., & Pessa, M. V. (1986). Atomic layer epitaxy. Journal of Applied Physics, 60(3), R65–R82.

Ritala, M., & Leskelä, M. (1999). Atomic layer epitaxy—a valuable tool for nanotechnology? Nanotechnology, 10(1), 19–24.

Nalwa, H. S. (2001). Handbook of thin films. Massachusetts: Academic Press.

Leskelä, M., & Ritala, M. (2002). Atomic layer deposition (ALD): from precursors to thin film structures. Thin Solid Films, 409(1), 138–146.

Kim, H. (2003). Atomic layer deposition of metal and nitride thin films: current research efforts and applications for semiconductor device processing. Journal of Vacuum Science and Technology B, 21(6), 2231–2261.

Leskelä, M., & Ritala, M. (2003). Atomic layer deposition chemistry: recent developments and future challenges. Angewandte Chemie International Edition, 42(45), 5548–5554.

Niinistö, L., Päiväsaari, J., Niinistö, J., Putkonen, M., & Nieminen, M. (2004). Advanced electronic and optoelectronic materials by atomic layer deposition: an overview with special emphasis on recent progress in processing of high-k dielectrics and other oxide materials. Physica Status Solidi A, 201(7), 1443–1452.

Puurunen, R. L. (2005). Surface chemistry of atomic layer deposition: a case study for the trimethylaluminum/water process. Journal of Applied Physics, 97(12), 9.

Knez, M., Nielsch, K., & Niinistö, L. (2007). Synthesis and surface engineering of complex nanostructures by atomic layer deposition. Advanced Materials, 19(21), 3425–3438.

Kim, H., Lee, H. B. R., & Maeng, W. J. (2009). Applications of atomic layer deposition to nanofabrication and emerging nanodevices. Thin Solid Films, 517(8), 2563–2580.

George, S. M. (2010). Atomic layer deposition: an overview. Chemical Reviews, 110(1), 111–131.

Detavernier, C., Dendooven, J., Pulinthanathu Sree, S., Ludwig, K. F., & Martens, J. A. (2011). Tailoring nanoporous materials by atomic layer deposition. Chemical Society Reviews, 40(11), 5242–5253.

Shim, J. H., Choi, H. J., Kim, Y., Torgersen, J., An, J., Lee, M. H., et al. (2017). Process-property relation in high-k ALD SrTiO3 and BaTiO3: a review. Journal of Materials Chemistry C, 5(32), 8000–8013.

Marichy, C., Bechelany, M., & Pinna, N. (2012). Atomic layer deposition of nanostructured materials for energy and environmental applications. Advanced Materials, 24(8), 1017–1032.

Pinna, N., & Knez, M. (2012). Atomic layer deposition of nanostructured materials. New York: Wiley.

Jiang, S. P., & Shen, P. K. (2013). Nanostructured and Advanced Materials for Fuel Cells. Boca Raton: CRC Press.

Shim, J. H., Chao, C.-C., Huang, H., & Prinz, F. B. (2007). Atomic layer deposition of yttria-stabilized zirconia for solid oxide fuel cells. Chemistry of Materials, 19(15), 3850–3854.

Brahim, C., Ringuedé, A., Cassir, M., Putkonen, M., & Niinistö, L. (2007). Electrical properties of thin yttria-stabilized zirconia overlayers produced by atomic layer deposition for solid oxide fuel cell applications. Applied Surface Science, 253(8), 3962–3968.

Su, P.-C., Chao, C.-C., Shim, J. H., Fasching, R., & Prinz, F. B. (2008). Solid oxide fuel cell with corrugated thin film electrolyte. Nano Letters, 8(8), 2289–2292.

Shim, J. H., Park, J. S., An, J., Gür, T. M., Kang, S., & Prinz, F. B. (2009). Intermediate-temperature ceramic fuel cells with thin film yttrium-doped barium zirconate electrolytes. Chemistry of Materials, 21(14), 3290–3296.

Chao, C. C., Kim, Y. B., & Prinz, F. B. (2009). Surface modification of yttria-stabilized zirconia electrolyte by atomic layer deposition. Nano Letters, 9(10), 3626–3628.

Holme, T. P., Lee, C., & Prinz, F. B. (2008). Atomic layer deposition of lsm cathodes for solid oxide fuel cells. Solid State Ionics, 179(27), 1540–1544.

Jiang, X., Huang, H., Prinz, F. B., & Bent, S. F. (2008). Application of atomic layer deposition of platinum to solid oxide fuel cells. Chemistry of Materials, 20(12), 3897–3905.

Balĺee, E., Ringuedé, A., Cassir, M., Putkonen, M., & Niinisẗo, L. (2009). Synthesis of a thin-layered ionic conductor, CeO2-Y2O3, by atomic layer deposition in view of solid oxide fuel cell applications. Chemistry of Materials, 21(19), 4614–4619.

Christensen, S. T., Elam, J. W., Rabuffetti, F. A., Ma, Q., Weigand, S. J., Lee, B., et al. (2009). Controlled growth of platinum nanoparticles on strontium titanate nanocubes by atomic layer deposition. Small (Weinheim an der Bergstrasse, Germany), 5(6), 750–757.

Christensen, S. T., Feng, H., Libera, J. L., Guo, N., Miller, J. T., Stair, P. C., et al. (2010). Supported Ru − Pt bimetallic nanoparticle catalysts prepared by atomic layer deposition. Nano Letters, 10(8), 3047–3051.

Shim, J. H., Jiang, X., Bent, S. F., & Prinz, F. B. (2010). Catalysts with pt surface coating by atomic layer deposition for solid oxide fuel cells. Journal of the Electrochemical Society, 157(6), B793–B797.

Park, J. S., Kim, Y. B., Shim, J. H., Kang, S., Gür, T. M., & Prinz, F. B. (2010). Evidence of proton transport in atomic layer deposited yttria-stabilized zirconia films. Chemistry of Materials, 22(18), 5366–5370.

Chao, C. C., Hsu, C. M., Cui, Y., & Prinz, F. B. (2011). Improved solid oxide fuel cell performance with nanostructured electrolytes. ACS Nano, 5(7), 5692–5696.

Kwon, C. W., Son, J. W., Lee, J. H., Kim, H. M., Lee, H. W., & Kim, K. B. (2011). High-performance micro-solid oxide fuel cells fabricated on nanoporous anodic aluminum oxide templates. Advanced Functional Materials, 21(6), 1154–1159.

Fan, Z., Chao, C. C., Hossein-Babaei, F., & Prinz, F. B. (2011). Improving solid oxide fuel cells with yttria-doped ceria interlayers by atomic layer deposition. Journal of Materials Chemistry, 21(29), 10903–10906.

Fan, Z., & Prinz, F. B. (2011). Enhancing oxide ion incorporation kinetics by nanoscale yttria-doped ceria interlayers. Nano Letters, 11(6), 2202–2205.

An, J., Kim, Y. B., Park, J., Gür, T. M., & Prinz, F. B. (2013). Three-dimensional nanostructured bilayer solid oxide fuel cell with 1.3 w/cm2 at 450 C. Nano Letters, 13(9), 4551–4555.

Son, K. S., Bae, K., Kim, J. W., Ha, J. S., & Shim, J. H. (2013). Ion conduction in nanoscale yttria-stabilized zirconia fabricated by atomic layer deposition with various doping rates. Journal of Vacuum Science and Technology A, 31(1), 01A107.

Kim, H. K., Jang, D. Y., Kim, J. W., Bae, K., & Shim, J. H. (2015). Ionic properties of ultrathin yttria-stabilized zirconia thin films fabricated by atomic layer deposition with water, oxygen, and ozone. Thin Solid Films, 589, 441–445.

Jang, D. Y., Kim, H. K., Kim, J. W., Bae, K., Schlupp, M. V. F., Park, S. W., et al. (2015). Low-temperature performance of yttria-stabilized zirconia prepared by atomic layer deposition. Journal of Power Sources, 274, 611–618.

An, J., Kim, Y. B., Gür, T. M., & Prinz, F. B. (2012). Enhancing charge transfer kinetics by nanoscale catalytic cermet interlayer. ACS Applied Materials & Interfaces, 4(12), 6790–6795.

Gong, Y., Palacio, D., Song, X., Patel, R. L., Liang, X., Zhao, X., et al. (2013). Stabilizing nanostructured solid oxide fuel cell cathode with atomic layer deposition. Nano Letters, 13(9), 4340–4345.

Gong, Y., Patel, R. L., Liang, X., Palacio, D., Song, X., Goodenough, J. B., et al. (2013). Atomic layer deposition functionalized composite sofc cathode La0.6Sr0.4Fe0.8Co0.2O3-δ-Gd0.2Ce0.8O1.9: enhanced long-term stability. Chemistry of Materials, 25(21), 4224–4231.

Will, J., Mitterdorfer, A., Kleinlogel, C., Perednis, D., & Gauckler, L. J. (2000). Fabrication of thin electrolytes for second-generation solid oxide fuel cells. Solid State Ionics, 131(1), 79–96.

An, J., Kim, Y. B., Jung, H. J., Park, J. S., Cha, S. W., Gür, T. M., et al. (2012). Structural and compositional analysis of solid oxide fuel cell electrolytes using transmission electron microscopy. International Journal of Precision Engineering and Manufacturing, 13(7), 1273–1279.

Kim, Y., Noh, S., Cho, G. Y., Park, T., Lee, Y. H., Yu, W., et al. (2016). Characterization of thin film solid oxide fuel cells with variations in the thickness of nickel oxide-gadolinia doped ceria anode. International Journal of Precision Engineering and Manufacturing, 17(8), 1079–1083.

Suntola, T. (1989). Atomic layer epitaxy. Materials Science Reports, 4(5), 261–312.

Chen, Y., Gerdes, K., & Song, X. (2016). Nanoionics and nanocatalysts: conformal mesoporous surface scaffold for cathode of solid oxide fuel cells. Scientific Reports, 6, 32997.

Park, S. W., Han, G. D., Choi, H. J., Prinz, F. B., & Shim, J. H. (2018). Evaluation of atomic layer deposited alumina as a protective layer for domestic silver articles: Anti-corrosion test in artificial sweat. Applied Surface Science, 441, 718–723.

Putkonen, M. (2002). Development of Low-temperature Deposition Processes by Atomic Layer Epitaxy for Binary and Ternary Oxide Thin Films. Espoo: Helsinki University of Technology.

Singh, J. A., Yang, N., & Bent, S. F. (2017). Nanoengineering heterogeneous catalysts by atomic layer deposition. Annual Review of Chemical and Biomolecular Engineering, 8, 41–62.

Wen, L., Zhou, M., Wang, C., Mi, Y., & Lei, Y. (2016). Nanoengineering energy conversion and storage devices via atomic layer deposition. Adv Energy Mater, 6(23), 1300468.

Kim, S. K., Lee, S. W., Han, J. H., Lee, B., Han, S., & Hwang, C. S. (2010). Capacitors with an equivalent oxide thickness of < 0.5 nm for nanoscale electronic semiconductor memory. Advanced Functional Materials, 20(18), 2989–3003.

Marichy, C., & Pinna, N. (2013). Carbon-nanostructures coated/decorated by atomic layer deposition: growth and applications. Coordination Chemistry Reviews, 257(23–24), 3232–3253.

Park, K.-H., Han, G. D., Neoh, K. C., Kim, T.-S., Shim, J. H., & Park, H.-D. (2017). Antibacterial activity of the thin ZnO film formed by atomic layer deposition under UV-A light. Chemical Engineering Journal, 328, 988–996.

Profijt, H. B., Potts, S. E., Van De Sanden, M. C. M., & Kessels, W. M. M. (2011). Plasma-assisted atomic layer deposition: basics, opportunities, and challenges. Journal of Vacuum Science and Technology A, 29(5), 050801.

Poodt, P., Cameron, D. C., Dickey, E., George, S. M., Kuznetsov, V., Parsons, G. N., et al. (2012). Spatial atomic layer deposition: a route towards further industrialization of atomic layer deposition. Journal of Vacuum Science and Technology A, 30(1), 010802.

Langston, M. C., Dasgupta, N. P., Jung, H. J., Logar, M., Huang, Y., Sinclair, R., et al. (2012). In situ cycle-by-cycle flash annealing of atomic layer deposited materials. Journal of Physical Chemistry C, 116(45), 24177–24183.

Henke, T., Knaut, M., Hossbach, C., Geidel, M., Albert, M., & Bartha, J. W. (2017). Growth of aluminum oxide thin films with enhanced film density by the integration of in situ flash annealing into low-temperature atomic layer deposition. Surface & Coatings Technology, 309, 600–608.

Cho, G. Y., Noh, S., Lee, Y. H., Ji, S., Hong, S. W., Koo, B., et al. (2016). Properties of nanostructured undoped ZrO2 thin film electrolytes by plasma enhanced atomic layer deposition for thin film solid oxide fuel cells. Journal of Vacuum Science and Technology A, 34(1), 01A151.

Kim, H., & Rossnagel, S. M. (2002). “Growth kinetics and initial stage growth during plasma-enhanced ti atomic layer deposition. Journal of Vacuum Science and Technology A, 20(3), 802–808.

Park, J. S., Park, H. S., & Kang, S. W. (2002). Plasma-enhanced atomic layer deposition of Ta-N thin films. Journal of the Electrochemical Society, 149(1), C28–C32.

Longrie, D., Deduytsche, D., & Detavernier, C. (2014). Reactor concepts for atomic layer deposition on agitated particles: A review. Journal of Vacuum Science and Technology A, 32(1), 010802.

Hoye, R. L. Z., Muñoz-Rojas, D., Nelson, S. F., Illiberi, A., Poodt, P., Roozeboom, F., et al. (2015). Research update: Atmospheric pressure spatial atomic layer deposition of ZnO thin films: Reactors, doping, and devices. APL Materials, 3(4), 040701.

Kim, S. K., Kim, W.-D., Kim, K.-M., Hwang, C. S., & Jeong, J. (2004). High dielectric constant TiO2 thin films on a ru electrode grown at 250 C by atomic-layer deposition. Applied Physics Letters, 85(18), 4112–4114.

Myung, S.-T., Izumi, K., Komaba, S., Sun, Y.-K., Yashiro, H., & Kumagai, N. (2005). Role of alumina coating on Li − Ni − Co − Mn − O particles as positive electrode material for lithium-ion batteries. Chemistry of Materials, 17(14), 3695–3704.

Zhang, W. M., Wu, X. L., Hu, J. S., Guo, Y. G., & Wan, L. J. (2008). Carbon coated Fe3O4 nanospindles as a superior anode material for lithium-ion batteries. Advanced Functional Materials, 18(24), 3941–3946.

Yu, M., Wang, A., Wang, Y., Li, C., & Shi, G. (2014). An alumina stabilized ZnO–graphene anode for lithium ion batteries via atomic layer deposition. Nanoscale, 6(19), 11419–11424.

Li, X., Meng, X., Liu, J., Geng, D., Zhang, Y., Banis, M. N., et al. (2012). Tin oxide with controlled morphology and crystallinity by atomic layer deposition onto graphene nanosheets for enhanced lithium storage. Advanced Functional Materials, 22(8), 1647–1654.

Steele, B. C., & Heinzel, A. (2001). Materials for fuel-cell technologies. Nature, 414(6861), 345–352.

Lashtabeg, A., & Skinner, S. J. (2006). Solid oxide fuel cells—a challenge for materials chemists? Journal of Materials Chemistry, 16(31), 3161–3170.

Fergus, J. W. (2005). Sealants for solid oxide fuel cells. Journal of Power Sources, 147(1), 46–57.

Fergus, J. W. (2005). Metallic interconnects for solid oxide fuel cells. Materials Science and Engineering A, 397(1), 271–283.

Wachsman, E. D., & Lee, K. T. (2011). Lowering the temperature of solid oxide fuel cells. Science, 334(6058), 935–939.

Wachsman, E. D., Marlowe, C. A., & Lee, K. T. (2012). Role of solid oxide fuel cells in a balanced energy strategy. Energy & Environmental Science, 5(2), 5498–5509.

De Souza, S., Visco, S. J., & De Jonghe, L. C. (1997). Thin-film solid oxide fuel cell with high performance at low-temperature. Solid State Ionics, 98(1–2), 57–61.

O’hayre, R., Cha, S. W., Prinz, F. B., & Colella, W. (2016). Fuel Cell Fundamentals. New York: Wiley.

Adler, S. B. (2004). Factors governing oxygen reduction in solid oxide fuel cell cathodes. Chemical Reviews, 104(10), 4791–4843.

Sun, C., Hui, R., & Roller, J. (2010). Cathode materials for solid oxide fuel cells: a review. Journal of Solid State Electrochemistry, 14(7), 1125–1144.

Jiang, S. P. (2008). Development of lanthanum strontium manganite perovskite cathode materials of solid oxide fuel cells: a review. Journal of Materials Science, 43(21), 6799–6833.

Tsipis, E. V., & Kharton, V. V. (2008). Electrode materials and reaction mechanisms in solid oxide fuel cells: a brief review. Journal of Solid State Electrochemistry, 12(9), 1039–1060.

Adler, S. B., Lane, J. A., & Steele, B. C. H. (1996). Electrode kinetics of porous mixed-conducting oxygen electrodes. Journal of the Electrochemical Society, 143(11), 3554–3564.

Fleig, J. (2003). Solid oxide fuel cell cathodes: polarization mechanisms and modeling of the electrochemical performance. Annual Review of Materials Science, 33(1), 361–382.

Gao, Z., Mogni, L. V., Miller, E. C., Railsback, J. G., & Barnett, S. A. (2016). A perspective on low-temperature solid oxide fuel cells. Energy & Environmental Science, 9(5), 1602–1644.

Vohs, J. M., & Gorte, R. J. (2009). High-performance SOFC cathodes prepared by infiltration. Advanced Materials, 21(9), 943–956.

Sholklapper, T. Z., Kurokawa, H., Jacobson, C., Visco, S., & De Jonghe, L. (2007). Nanostructured solid oxide fuel cell electrodes. Nano Letters, 7(7), 2136–2141.

Jung, W., & Tuller, H. L. (2012). Investigation of surface sr segregation in model thin film solid oxide fuel cell perovskite electrodes. Energy & Environmental Science, 5(1), 5370–5378.

Cai, Z., Kubicek, M., Fleig, J. R., & Yildiz, B. (2012). Chemical heterogeneities on La0.6Sr0.4CoO3−δ thin films—correlations to cathode surface activity and stability. Chemistry of Materials, 24(6), 1116–1127.

Lee, W., Han, J. W., Chen, Y., Cai, Z., & Yildiz, B. (2013). Cation size mismatch and charge interactions drive dopant segregation at the surfaces of manganite perovskites. Journal of the American Chemical Society, 135(21), 7909–7925.

Crumlin, E. J., Mutoro, E., Liu, Z., Grass, M. E., Biegalski, M. D., Lee, Y.-L., et al. (2012). Surface strontium enrichment on highly active perovskites for oxygen electrocatalysis in solid oxide fuel cells. Energy & Environmental Science, 5(3), 6081–6088.

Li, Y. K., Choi, H. J., Kim, H. K., Chean, N. K., Kim, M., Koo, J., et al. (2015). Nanoporous silver cathodes surface-treated by atomic layer deposition of Y:ZrO2 for high-performance low-temperature solid oxide fuel cells. Journal of Power Sources, 295, 175–181.

Neoh, K. C., Han, G. D., Kim, M., Kim, J. W., Choi, H. J., Park, S. W., et al. (2016). Nanoporous silver cathode surface treated by atomic layer deposition of CeOx for low-temperature solid oxide fuel cells. Nanotechnology, 27(18), 185403.

Chang, I., Ji, S., Park, J., Lee, M. H., & Cha, S. W. (2015). Ultrathin ysz coating on Pt cathode for high thermal stability and enhanced oxygen reduction reaction activity. Adv. Energy Mater., 5(10), 1402251.

Chang, I., Kim, D., Lee, Y., Hong, S.-H., & Cha, S. W. (2016). Effect of ultra-thin SnO2 coating on Pt catalyst for energy applications. International Journal of Precision Engineering and Manufacturing, 17(5), 691–694.

Karimaghaloo, A., Andrade, A. M., Grewal, S., Shim, J. H., & Lee, M. H. (2017). Mechanism of cathodic performance enhancement by a few-nanometer-thick oxide overcoat on porous Pt cathodes of solid oxide fuel cells. ACS Omega, 2(3), 806–813.

Küngas, R., Anthony, S. Y., Levine, J., Vohs, J. M., & Gorte, R. J. (2013). An investigation of oxygen reduction kinetics in lsf electrodes. Journal of the Electrochemical Society, 160(2), F205–F211.

Anthony, S. Y., Küngas, R., Vohs, J. M., & Gorte, R. J. (2013). Modification of SOFC cathodes by atomic layer deposition. Journal of the Electrochemical Society, 160(11), F1225–F1231.

Kim, E.-H., Jung, H.-J., An, K.-S., Park, J.-Y., Lee, J., Hwang, I.-D., et al. (2014). Degradation of La0.6Sr0.4CoO3-based cathode performance in solid oxide fuel cells due to the presence of aluminum oxide deposited through atomic layer deposition. Ceramics International, 40(6), 7817–7822.

Choi, H. J., Bae, K., Jang, D. Y., Kim, J. W., & Shim, J. H. (2015). Performance degradation of lanthanum strontium cobaltite after surface modification. Journal of the Electrochemical Society, 162(6), F622–F626.

Nilsen, O., Rauwel, E., Fjellvåg, H., & Kjekshus, A. (2007). Growth of La1−xCaxMnO3 thin films by atomic layer deposition. Journal of Materials Chemistry, 17(15), 1466–1475.

Lie, M., Nilsen, O., Fjellvåg, H., & Kjekshus, A. (2009). Growth of La 1−xSrxFeO3 thin films by atomic layer deposition. Dalton Transactions, 3, 481–489.

Ahvenniemi, E., Matvejeff, M., & Karppinen, M. (2015). Atomic layer deposition of quaternary oxide (La, Sr)CoO3−δ thin films. Dalton Transactions, 44(17), 8001–8006.

Brahim, C., Chauveau, F., Ringuedé, A., Cassir, M., Putkonen, M., & Niinistö, L. (2009). ZrO2–In2O3 thin layers with gradual ionic to electronic composition synthesized by atomic layer deposition for sofc applications. Journal of Materials Chemistry, 19(6), 760–766.

Seim, H., Nieminen, M., Niinistö, L., Fjellvåg, H., & Johansson, L.-S. (1997). Growth of LaCoO3 thin films from β-diketonate precursors. Applied Surface Science, 112, 243–250.

Nilsen, O., Peussa, M., Fjellvåg, H., Niinistö, L., & Kjekshus, A. (1999). Thin film deposition of lanthanum manganite perovskite by the ALE process. Journal of Materials Chemistry, 9(8), 1781–1784.

Chao, C. C., Motoyama, M., & Prinz, F. B. (2012). Nanostructured platinum catalysts by atomic-layer deposition for solid-oxide fuel cells. Advanced Energy Materials, 2(6), 651–654.

An, J., Kim, Y.-B., & Prinz, F. B. (2013). Ultra-thin platinum catalytic electrodes fabricated by atomic layer deposition. Physical Chemistry Chemical Physics: PCCP, 15(20), 7520–7525.

Ji, S., Chang, I., Cho, G. Y., Lee, Y. H., Shim, J. H., & Cha, S. W. (2014). Application of dense nano-thin platinum films for low-temperature solid oxide fuel cells by atomic layer deposition. International Journal of Hydrogen Energy, 39(23), 12402–12408.

Jeong, H. J., Kim, J. W., Bae, K., Jung, H., & Shim, J. H. (2015). Platinum–ruthenium heterogeneous catalytic anodes prepared by atomic layer deposition for use in direct methanol solid oxide fuel cells. ACS Catalysis, 5(3), 1914–1921.

Jeong, H., Kim, J. W., Park, J., An, J., Lee, T., Prinz, F. B., et al. (2016). Bimetallic nickel/ruthenium catalysts synthesized by atomic layer deposition for low-temperature direct methanol solid oxide fuel cells. ACS Applied Materials & Interfaces, 8(44), 30090–30098.

Jeong, H. J., Kim, J. W., Jang, D. Y., & Shim, J. H. (2015). Atomic layer deposition of ruthenium surface-coating on porous platinum catalysts for high-performance direct ethanol solid oxide fuel cells. Journal of Power Sources, 291, 239–245.

Gür, T. M., Bent, S. F., & Prinz, F. B. (2014). Nanostructuring materials for solar-to-hydrogen conversion. Journal of Physical Chemistry C, 118(37), 21301–21315.

Tsvetkov, N., Lu, Q., Sun, L., Crumlin, E. J., & Yildiz, B. (2016). Improved chemical and electrochemical stability of perovskite oxides with less reducible cations at the surface. Nature Materials, 15(9), 1010–1016.

Rupp, G. M., Opitz, A. K., Nenning, A., Limbeck, A., & Fleig, J. (2017). Real-time impedance monitoring of oxygen reduction during surface modification of thin film cathodes. Nature Materials, 16(6), 640–645.

Myung, J., Neagu, D., Miller, D. N., & Irvine, J. T. (2016). Switching on electrocatalytic activity in solid oxide cells. Nature, 537, 528–531.

Irvine, J. T., Neagu, D., Verbraeken, M. C., Chatzichristodoulou, C., Graves, C., & Mogensen, M. B. (2016). Evolution of the electrochemical interface in high-temperature fuel cells and electrolysers. Nature Energy, 1, 15014.

Neagu, D., Oh, T.-S., Miller, D. N., Ménard, H., Bukhari, S. M., Gamble, S. R., et al. (2015). Nano-socketed nickel particles with enhanced coking resistance grown in situ by redox exsolution. Nature Communications, 6, 8120.

Zhu, Y., Zhou, W., Ran, R., Chen, Y., Shao, Z., & Liu, M. (2015). Promotion of oxygen reduction by exsolved silver nanoparticles on a perovskite scaffold for low-temperature solid oxide fuel cells. Nano Letters, 16(1), 512–518.

Yildiz, B. (2014). “Stretching” the energy landscape of oxides—effects on electrocatalysis and diffusion. MRS Bulletin, 39(2), 147–156.

Lee, Y.-L., Kleis, J., Rossmeisl, J., Shao-Horn, Y., & Morgan, D. (2011). Prediction of solid oxide fuel cell cathode activity with first-principles descriptors. Energy & Environmental Science, 4(10), 3966–3970.

Kushima, A., Yip, S., & Yildiz, B. (2010). Competing strain effects in reactivity of LaCoO3 with oxygen. Physical Review B, 82(11), 115435.

Kubicek, M., Cai, Z., Ma, W., Yildiz, B., Hutter, H., & Fleig, J. R. (2013). Tensile lattice strain accelerates oxygen surface exchange and diffusion in La1–xSrxCoO3−δ thin films. ACS Nano, 7(4), 3276–3286.

Tsvetkov, N., Lu, Q., Chen, Y., & Yildiz, B. (2015). Accelerated oxygen exchange kinetics on Nd2NiO4+δ thin films with tensile strain along c-axis. ACS Nano, 9(2), 1613–1621.

Petrie, J. R., Mitra, C., Jeen, H., Choi, W. S., Meyer, T. L., Reboredo, F. A., et al. (2016). Strain control of oxygen vacancies in epitaxial strontium cobaltite films. Advanced Functional Materials, 26(10), 1564–1570.

McDaniel, M. D., Ngo, T. Q., Hu, S., Posadas, A., Demkov, A. A., & Ekerdt, J. G. (2015). Atomic layer deposition of perovskite oxides and their epitaxial integration with si, ge, and other semiconductors. Applied Physical Review, 2(4), 041301.

Acknowledgements

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and the Ministry of Trade, Industry & Energy (MOTIE) of the Republic of Korea (No. 20173010032170). T.M.G., Y.K., F.B.P, T.D.S., S.X. sincerely appreciate the Volkswagen group for financial support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shim, J.H., Han, G.D., Choi, H.J. et al. Atomic Layer Deposition for Surface Engineering of Solid Oxide Fuel Cell Electrodes. Int. J. of Precis. Eng. and Manuf.-Green Tech. 6, 629–646 (2019). https://doi.org/10.1007/s40684-019-00092-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40684-019-00092-7